Our SMART solutions for your industrial equipment

Industry 4.0

Today, the composite parts manufacturing industry is constantly challenged to produce ever larger volumes at ever lower costs. It also faces four major challenges in its production processes: raw material costs, carbon footprint, reliability and labor costs.

At Techni-Modul Engineering, our expertise is to bring innovations to reach your goals. These SMART solutions have been created to optimize your production by reducing cycle time, increasing quality and repeatability and improving the work environment: this is the key to optimization.

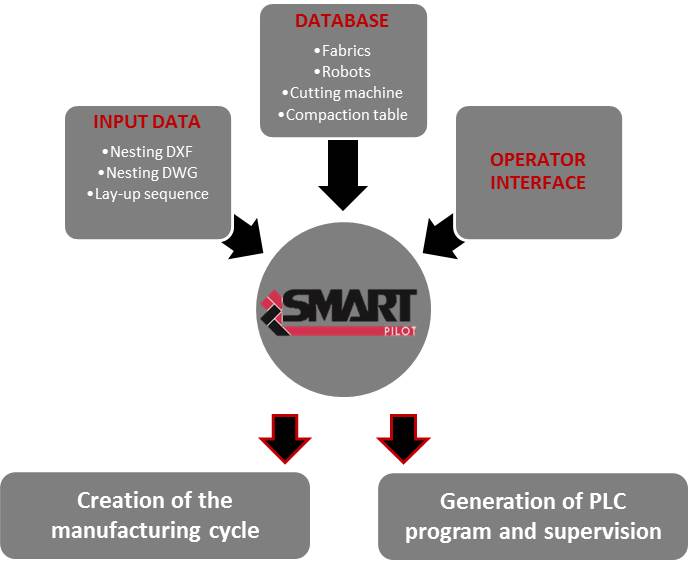

All SMART solutions are supervised by a single MES (Manufacturing Execution System): SMART Pilot, which ensures perfect interoperability between SMART solutions.

• Quality inspection of plies during lay-up (shape, positioning,…)

• Accuracy (± 0.2 mm) and reliability

• Suitable for Pick & Place robotic arm or other system (3 axis,…)

• Fully modular system (plug & play software + camera system)

•Replaces the presence of a quality controller for Class 1 parts

SHAPE IDENTIFICATION :

SMART CONTROL identifies the folds in relation to their real shape, calculates their position and their precise orientation in space.FIBER ORIENTATION CONTROL :

SMART CONTROL controls the fiber orientation of the plie before and after positioning (0.2°).PLY POSITIONING :

SMART CONTROL detects the actual fold contours and allows a comparison between the theoretical and actual position of the fold edges.FOD AND MATERIAL DEFECTS :

SMART CONTROL detects and locates defects on composite materials, detects the presence of foreign objects on the ply (size > 0.2cm²) and locates their positions.

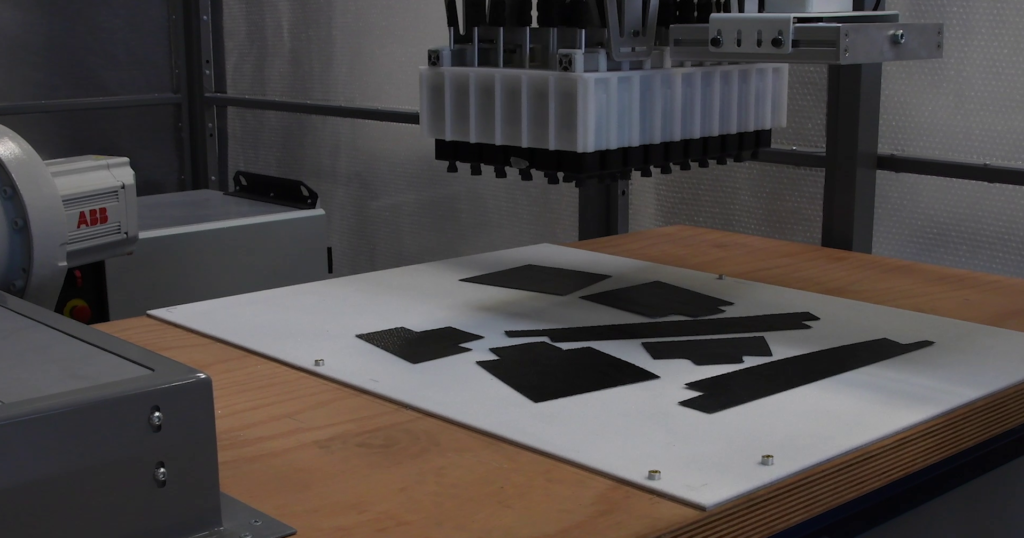

• Unique standardized module (500x300mm)) • Several modules can be combined to handle larger folds • 60 independently controlled suction cups allow you to pick up folds of different sizes and shapes

• Reliability: automated cycle • Time:easy cleaning of the SMART INJECTION block and no injection machine cleaning • Ecological: no resin waste in the injection machine and in the injection pipes • Decrease consumables cost: no injection pipes

The injection machine is also available with a capacity up to 60cl, and with a pressure up to 20 bar (optional).

Example of comparison for an 800g part made in RTM (400g of resin).

| Comparison | Injection machine | SMART Injection | Conclusion |

|---|---|---|---|

| Labor | 30 minutes | 15 minutes | - 50% |

| Consumables | 55€ | 8€ | - 89% |

| Resin waste | 200g | 40g | - 80% |

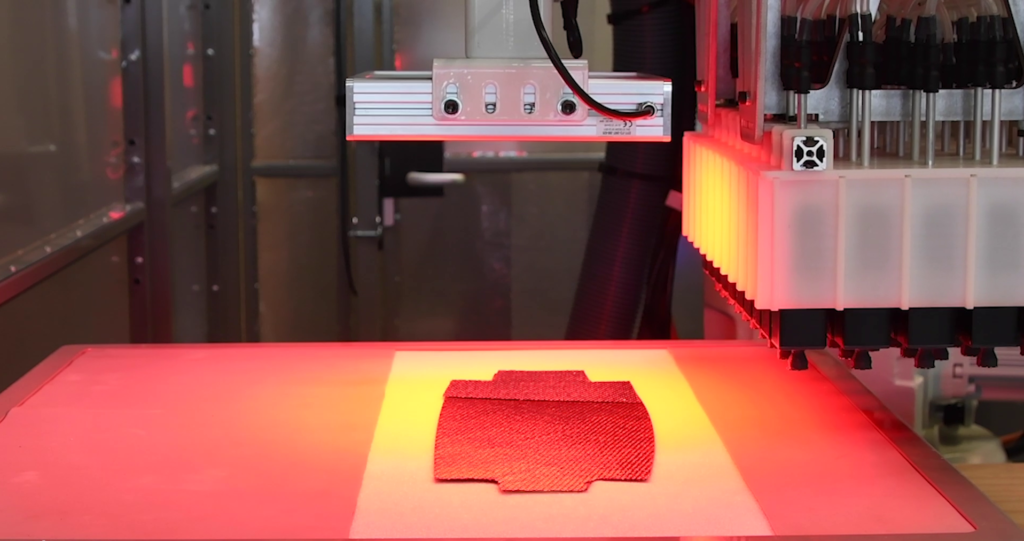

Today, most composite parts are draped manually and in order to meet increasing production rates, we totally re-examined this production process by developing an automated technology capable of taking one or more plies from an initial reference and placing them in their final position (flat or 3D) according to the lay-up plan (SMART Pick & Place).

Our SMART Control solution can complement the SMART Pick & Place in order to check at 100% the confirmity of the draping.

• Reduction of cycle time

• Improved quality and repeatability for production

• Improvement of the working environment

• Adaptable to different composite materials (dry and prepreg materials)

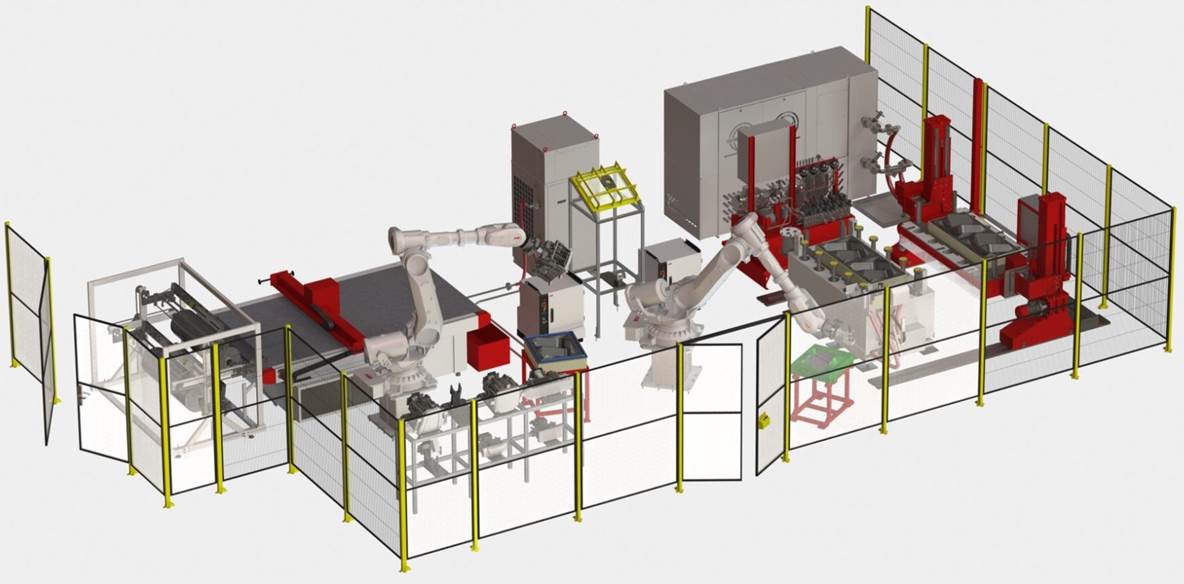

Customised industrial machine

Depending on your needs

Standardised industrial machine

SMART Stacking solution

Designed according to demand. Different configuration possibilities according to the requirements.

Example of configuration :

- Unwinding of the material

- Draping and shaping of folds

- Lay-up control (SMART Control)

- Compaction

- Preform trimming

- Preform assembly

- Closing of the injection mould

Solution designed for the automatic production of stacks (2 plies per minute. This solution includes the universal gripper (SMART Gripper) and the SMART Control.

Two references are available:

- Working area: 1000x600mm for plies with a maximum size of 500x300mm

- Working area: 2000x1000mm for plies with a maximum size of 1000x300mm